The color spectrophotometer is a vital tool in industries demanding precision, like automotive repair, manufacturing, and auto body work. It objectively measures light reflectance for accurate color assessment, streamlining processes, minimizing rework, saving costs, and enhancing customer satisfaction. In manufacturing, it detects defects early, while in auto body repair, it matches colors precisely to reduce waste and eliminate visible inconsistencies.

In today’s manufacturing landscape, minimizing rework and material waste is paramount. This is where a color spectrophotometer emerges as a powerful tool, revolutionizing quality control and production efficiency. By understanding and ensuring precise color measurement accuracy, these advanced devices play a pivotal role in reducing unnecessary rework. Moreover, they contribute to sustainable practices by optimizing material usage, making them an indispensable asset for any forward-thinking manufacturer. Discover how this technology is transforming industries.

- Understanding Color Measurement Accuracy with Spectrophotometry

- Reducing Rework: The Role of Spectrophotometers in Quality Control

- Efficient Material Usage: A Case for Color Spectrophotometer Technology

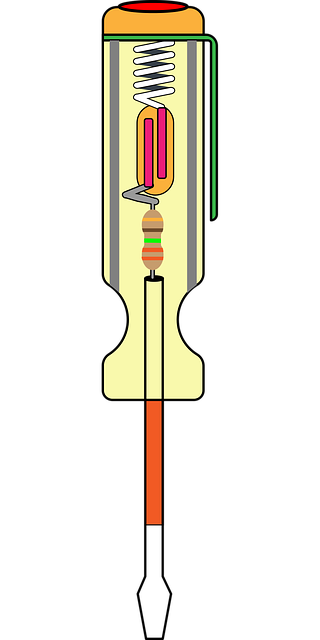

Understanding Color Measurement Accuracy with Spectrophotometry

Color measurement accuracy is paramount in industries where precision is key, such as automotive repair services and luxury vehicle repairs. This is where spectrophotometry steps in as a powerful tool. A color spectrophotometer measures the reflectance or transmittance of light at specific wavelengths, providing an objective and quantitative way to assess color.

By using this technology, auto painting processes can be refined, ensuring consistent and accurate color matches every time. This reduces the need for rework, which not only saves time but also minimizes material waste, making it an invaluable asset in any professional paint job, whether for a standard vehicle or a high-end luxury car.

Reducing Rework: The Role of Spectrophotometers in Quality Control

In the realm of manufacturing and especially automotive sectors like fleet repair services and car bodywork services, minimizing rework is key to maximizing efficiency and reducing costs. This is where color spectrophotometers play a pivotal role in quality control processes. By providing precise measurements of color and surface characteristics, these advanced tools enable thorough inspection of products before they leave the production line. This proactive approach ensures that defects, including minor scratches or inconsistencies, are identified early on, preventing them from escaping detection and leading to costly rework later down the line.

By integrating a color spectrophotometer into their quality control routines, manufacturers can significantly reduce the need for repetitive repairs and material waste associated with them. This technology allows for consistent and accurate assessments of color accuracy, gloss, and other essential surface properties, ensuring that every finished product meets stringent quality standards. Thus, it not only streamlines production but also enhances customer satisfaction by delivering flawless, high-quality finishes in scratch repair and car bodywork services.

Efficient Material Usage: A Case for Color Spectrophotometer Technology

In the realm of auto body shops and scratch repairs, efficient material usage is paramount to reducing waste and saving costs. Traditional methods often involve significant rework and excessive material consumption, especially in the case of a fender bender or minor dents. However, integrating color spectrophotometer technology into these processes offers a game-changing solution.

This innovative tool precisely measures and analyzes the color and composition of materials, enabling technicians to match repairs accurately. By minimizing the need for trial and error, it reduces the amount of material waste generated during scratch repair or minor bodywork. Moreover, the color spectrophotometer ensures that each repair is seamlessly blended with the surrounding surface, eliminating visible inconsistencies that might arise from less advanced techniques.

A color spectrophotometer is a powerful tool that significantly reduces rework and material waste by ensuring precise color measurement accuracy in quality control processes. By efficiently assessing and matching colors, this technology streamlines production lines, saves valuable resources, and ultimately contributes to more sustainable manufacturing practices. Adopting a color spectrophotometer can be the game-changer for industries seeking to optimize their operations while minimizing environmental impact.